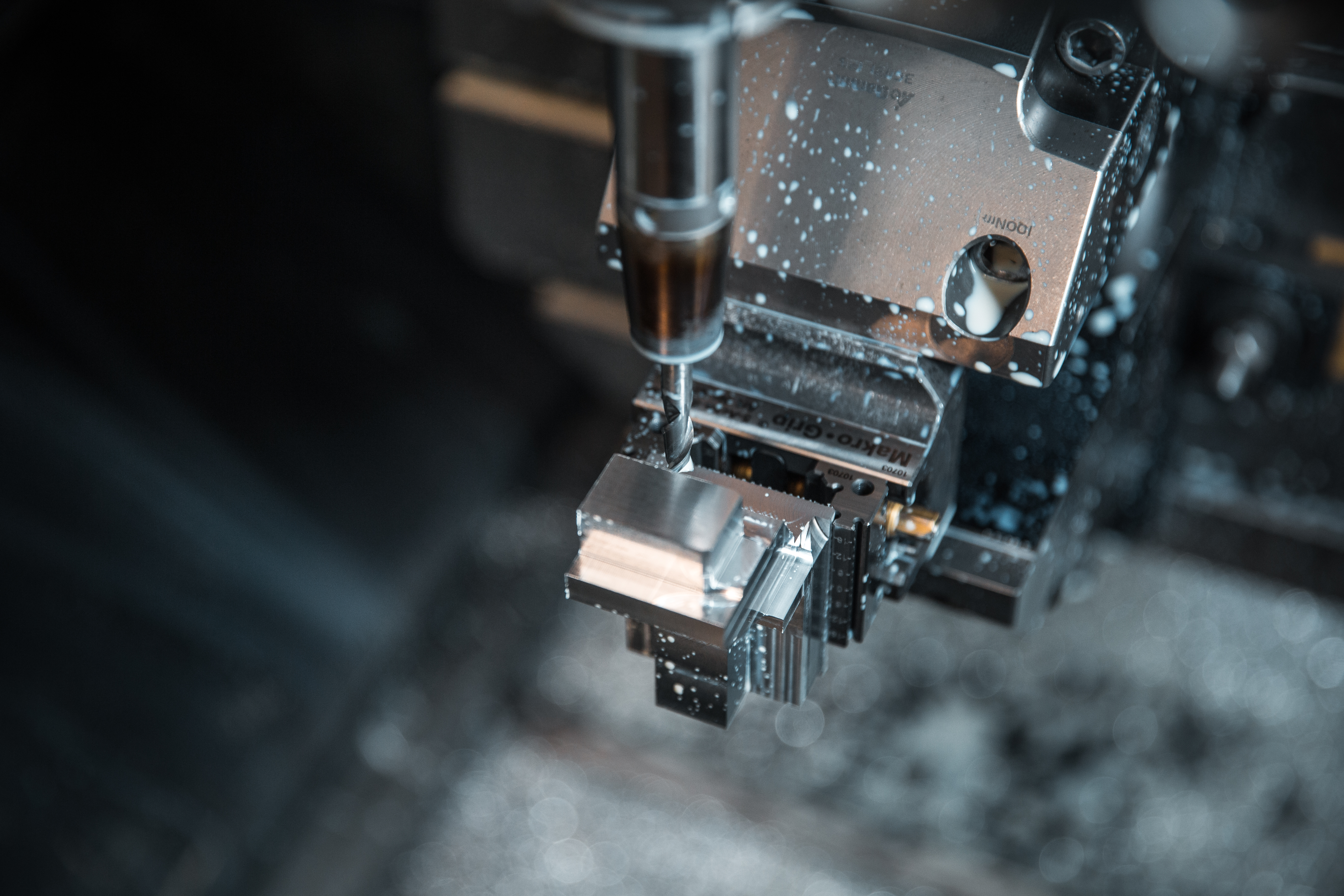

Vierrevi is a Company specializing in the machining of precision mechanical components.

It was founded in 1980 in Mirandola (Modena, Italy).

After years of constant growth and evolution, in 2017 it began an important process of corporate reorganization and at the same time, the official homologation for the F1 sector, starting the development of an excellent service.

Thanks to the 35 qualified employees and the cutting-edge available machines, Vierrevi is ready to renew the same challenge of excellence of its first 45 years of activity, pursuing new goals in the aerospace sector.

Vierrevi is engaged in the production of industrial mechanical components and prototypes and services are not limited to just turning and milling:

the Company strength is in providing a finished product, from the management of external steps, to assemblies and to supply’s control documents.

The departments structure allows to work alongside the customer from the prototyping stage.

Vierrevi team came about from the natural propensity to make even the most complex productions possible, taking charge of the customer’s problems.

In a market where often standards take second place, Vierrevi srl believes in attention to detail and uncompromising quality.

Each product for Vierrevi is unique: the Company is able to handle both a single unit batch as well as small batches series (up to 100pcs).

As a guarantee of the quality Vierrevi boast two main types of certification: ISO 9001:2015 and EN 9100:2018.

Vierrevi Srl mechanical precision workshop deals with the production, third-party processing, of all those industrial components for the aerospace, packaging, automatic machines and motorsports sectors.

The range of services includes processings such as milling, turning, cutting, assembly and dimensional measurements. To perform these operations to the best of its ability, Vierrevi uses a cutting-edge machine park, precise instruments and a competent staff who are able to manage any variable with professionalism and passion.

The Company use the best instruments including CAD-CAM programming software, schedulers and MES systems and it also creates pieces with cutting-edge CNC machines.

- DIMENSIONS TURNING: Min. diameter 10 mm – max 400 mm.

- DIMENSION MILLING: 3 axes max 500 x 1050 mm; 5 axes max 700 x 700 x 500 mm from slab – 2,000-4,000mm, th. up to 5 – 30 mm.

- MACHINED MATERIALS: Titanium, Duplex, Plastics, Aluminium, Steels, Superalloys (Inconel).

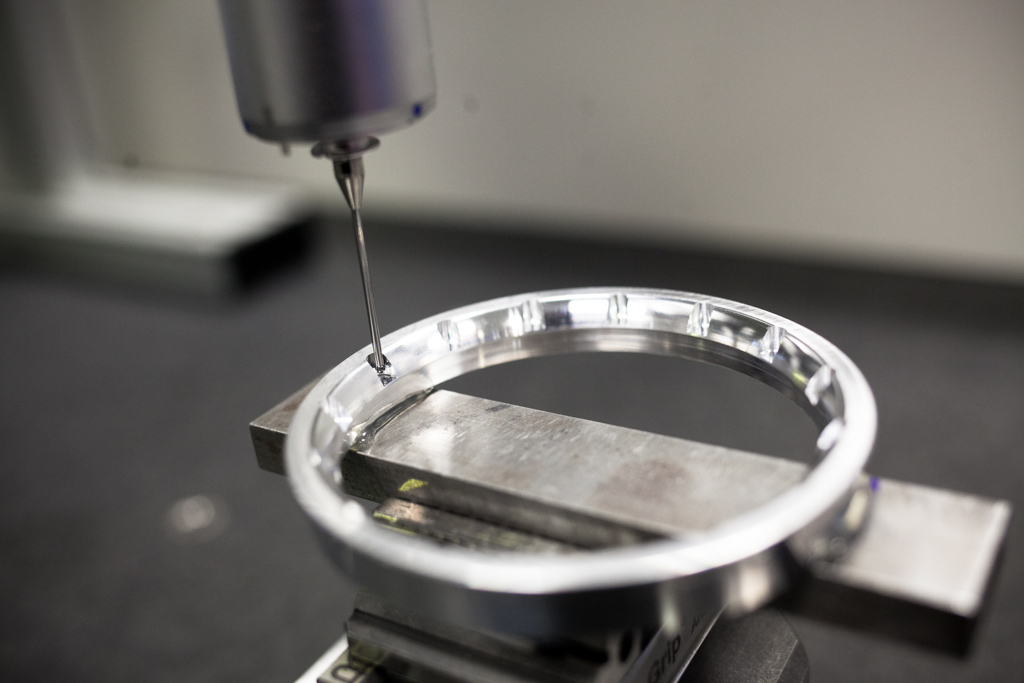

Vierrevi tests in-process all the realized products, right up to final testing.

Vierrevi has innovative technology and excellent equipments to perform the dimensional tests, that certify the conformity and the quality of the mechanical parts.